The Gold Standard in Purity Analysis

At KaratVision, we are committed to redefining the standards of precision in gold and metal testing. Our advanced instruments are trusted by professionals for their accuracy, reliability, and ease of use. Backed by innovation and integrity, we serve jewelers, traders, and industries that demand nothing but excellence

We are committed to innovation, continually pushing the boundaries of what's possible in elemental analysis to ensure our clients have the most reliable tools for their trade. Our mission is to empower your business with confidence in every transaction.

Get In TouchOur Philosophy

The principles that guide our innovation and service.

Our Mission

To deliver high-precision testing solutions that empower businesses with accurate and reliable results, enhancing trust and transparency in every transaction.

Our Vision

To be the global benchmark for gold testing innovation, driving the future of precious metal analysis with technology, precision, and trust.

Core Values

KaratVision delivers precise, innovative, and trusted solutions—built to last, customer-focused, and eco-conscious.

K1 Series

Professional-grade XRF analyzer with lab-level accuracy for precious metal testing.

Learn More

K2 Series

Portable and efficient gold testing machine with instant results and battery operation.

Learn More

K3 Series

Advanced analyzer with automated testing, data storage, and high-throughput capabilities.

Learn MoreOur Product Lineup

Discover our range of precision testing machines designed to meet every need in the precious metals industry. From portable solutions to laboratory-grade equipment, we have the perfect tool for your business.

Each product in our lineup incorporates our latest technological advancements, ensuring accuracy, reliability, and ease of use. Whether you're a small jewelry store or a large refining operation, we have a solution that fits your requirements.

Key Features of Our Technology

Engineered for excellence, designed for you.

Instant Analysis

Get precise elemental composition in seconds, not hours. Streamline your workflow and make faster, more informed decisions.

XRF Technology

Our core technology, X-Ray Fluorescence, provides lab-grade accuracy without damaging or altering your valuable items.

Non-Destructive

Test with confidence. Analyze finished jewelry, coins, and bullion without leaving a single mark or scratch.

User-Friendly Interface

With intuitive touchscreen controls and simple one-touch operation, our machines can be mastered in minutes, not days.

Comprehensive Reporting

Easily generate, save, and export professional certificates of analysis. Keep meticulous records for compliance and customer trust.

Built to Last

Constructed with high-quality components for maximum durability and reliability in demanding industrial environments.

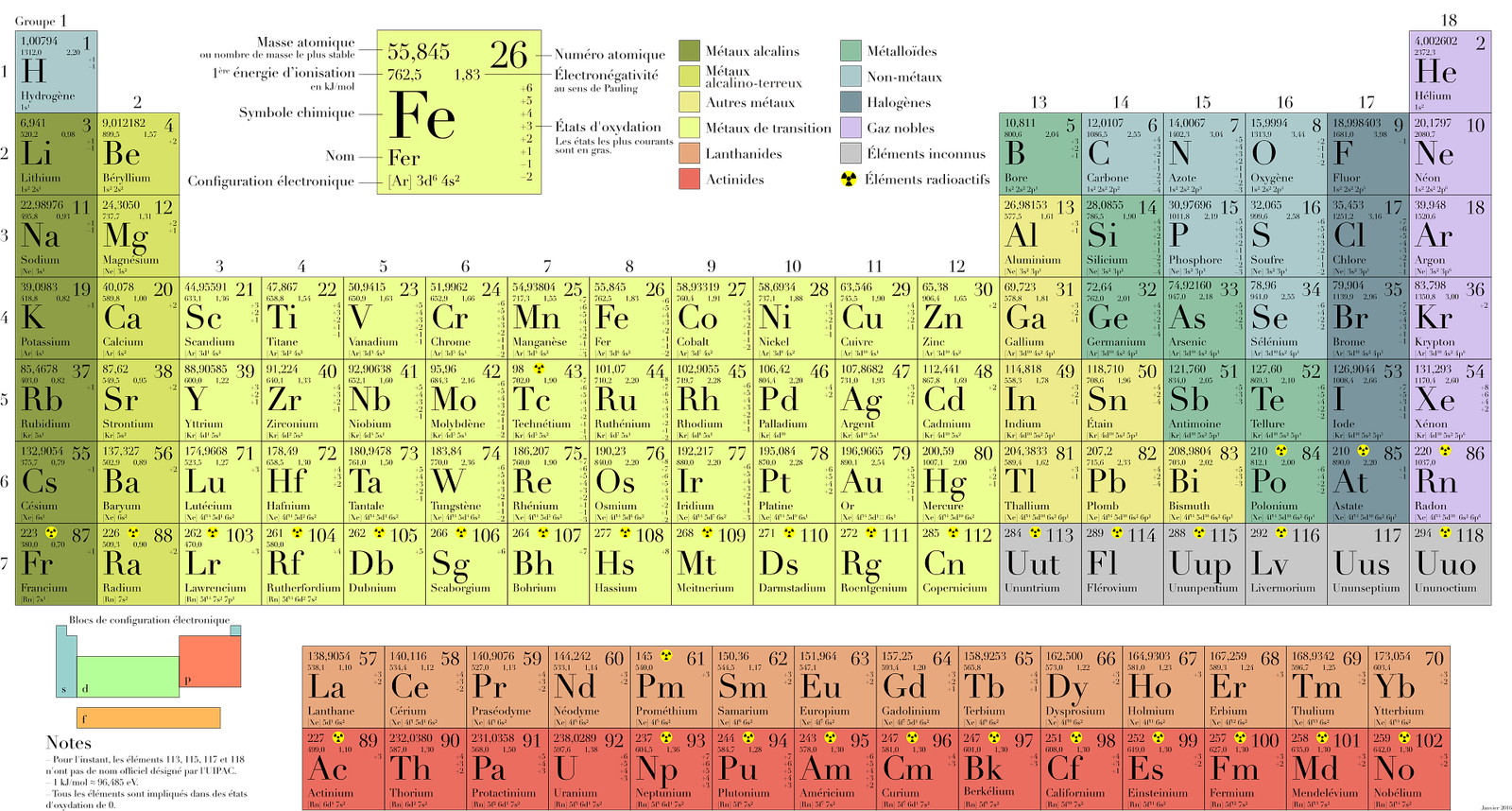

Elemental Analysis Technology

Our advanced technology analyzes elements across the periodic table with precision

KaratVision's technology utilizes advanced spectroscopic analysis to detect and measure elements across the periodic table, providing accurate composition analysis for precious metals and alloys.

Frequently Asked Questions

Have questions? We have answers.

Our flagship XRF spectrometers boast an accuracy of up to +/- 0.01%, ensuring you get the most precise readings for high-value items. Our portable models maintain an industry-leading accuracy for their class.

All our machines come factory-calibrated. We recommend an annual check-up and recalibration service to ensure peak performance and accuracy over time. We provide easy-to-use kits for minor self-calibration as well.

No, our primary technology is X-Ray Fluorescence (XRF), which is a completely non-destructive testing method. It analyzes the elemental composition of the item without leaving any marks or causing any damage to the piece.

Our analyzers can test a wide range of precious metals including gold, silver, platinum, palladium, and their alloys. They can also detect and measure common impurities and plating materials.

Results are typically available within 3-5 seconds for most applications. The exact time may vary slightly depending on the specific model and the complexity of the alloy being tested.